- Overview

- What is EPR for Tyre Waste?

- Regulations & Legal Framework

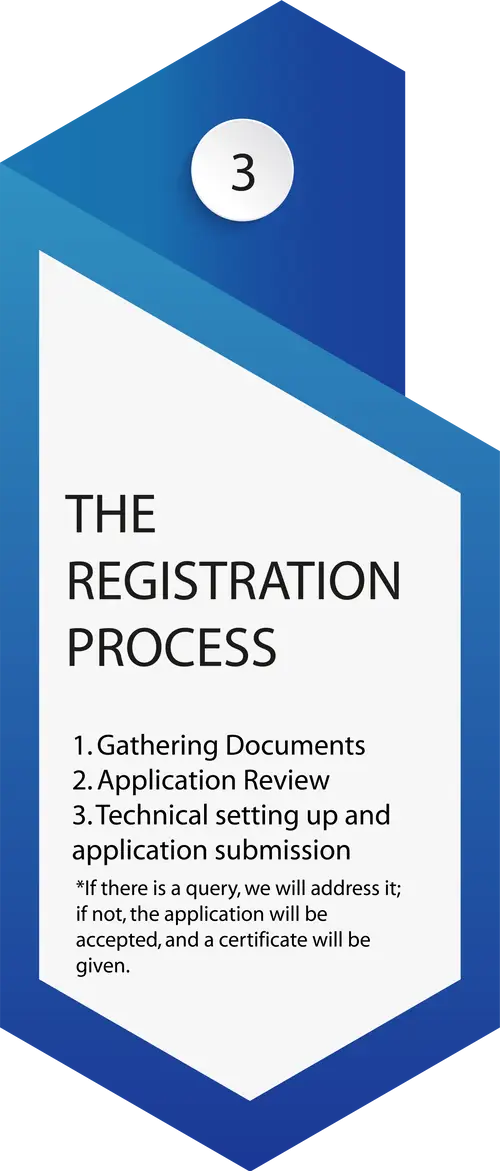

- Certification Process

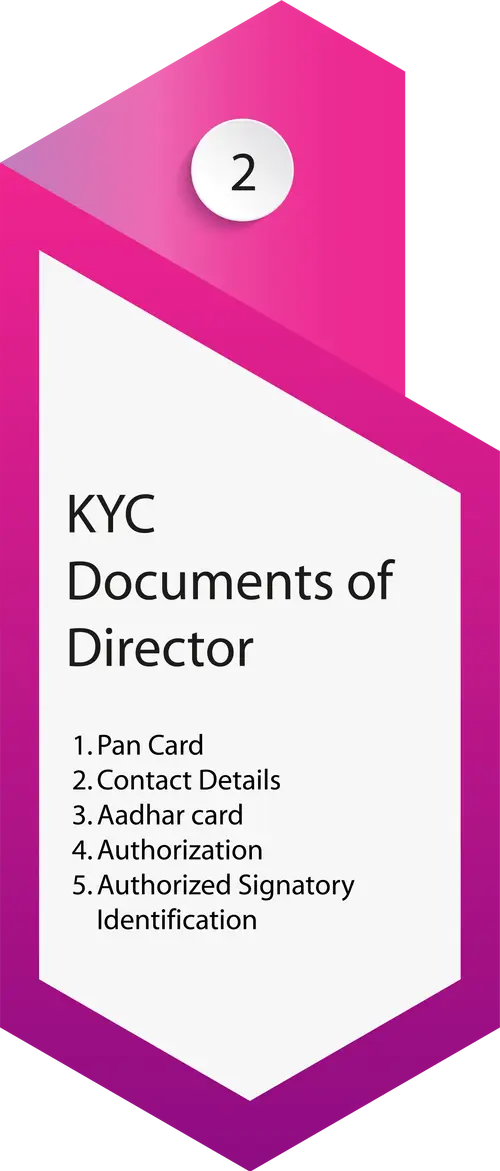

- Documents Required

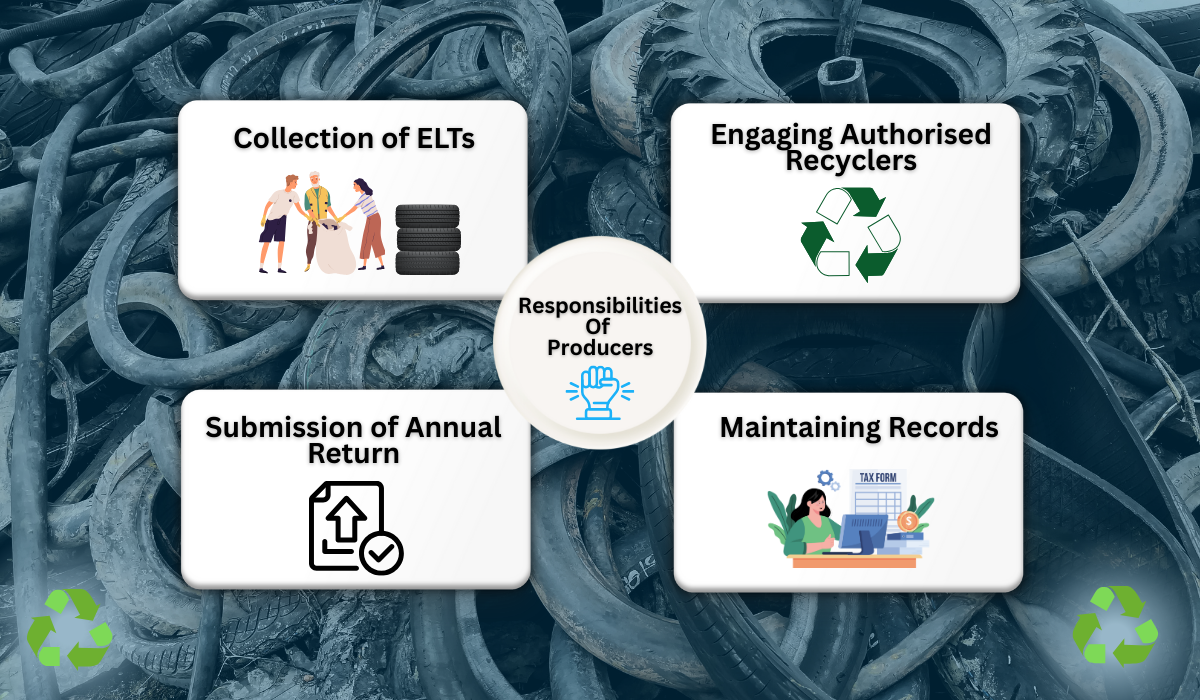

- Responsibilities of Producers under EPR for Tyre Waste

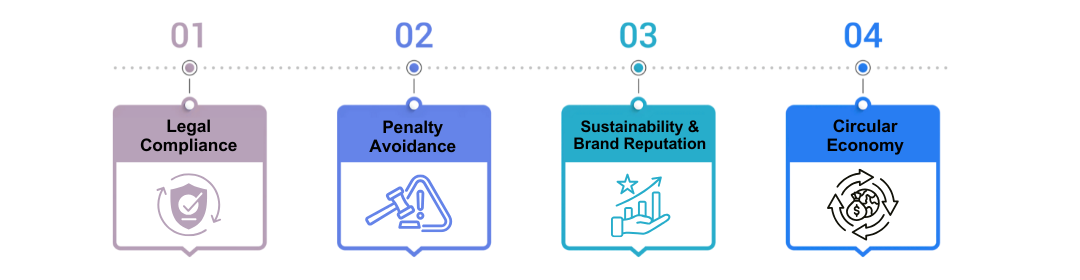

- Benefits of EPR Tyre Waste Certification

- How SS Global Services Helps

- Frequently Asked Questions (FAQ)

Overview

Tyre waste is a growing environmental challenge in India. Millions of End-of-Life Tyres (ELTs) are discarded every year, creating hazards such as soil and water pollution, fire risks, and mosquito breeding. Proper management of tyre waste is essential to protect the environment and public health.

To address this, the Government of India has introduced Extended Producer Responsibility (EPR) for tyre waste. Under this framework, tyre producers, importers, and brand owners are legally responsible for the collection, recycling, and safe disposal of used tyres. EPR ensures environmentally sound management while promoting recycling and resource recovery.

Complying with EPR not only fulfills the Tyre Waste Management Rules but also supports sustainability and circular economy initiatives. By implementing effective tyre waste management, businesses can reduce environmental impact, enhance corporate responsibility, and strengthen their brand reputation.

At SS Global Services, we provide expert guidance and end-to-end support for EPR registration for Tyre Waste management. Our team assists with documentation, liaison with CPCB authorities, and ensures fast, hassle-free compliance. Partner with us to simplify your tyre waste management process and stay fully compliant while enhancing your company’s sustainability credentials.

Get Service NowWhat is EPR for Tyre Waste?

Extended Producer Responsibility (EPR) for tyre waste is a regulatory framework that holds tyre producers, importers, and brand owners accountable for the collection, recycling, and environmentally sound disposal of End-of-Life Tyres (ELTs). Under this system, businesses must ensure that discarded tyres are properly managed to prevent environmental hazards such as soil and water pollution, fire risks, and mosquito breeding.

Through EPR registration for tyre waste management, producers and importers engage authorized recyclers or retreaders, maintain records, and report recycling activities to comply with the Tyre Waste Management Rules. Implementing EPR not only ensures regulatory compliance but also promotes sustainable recycling, resource recovery, and a circular economy, helping companies enhance their corporate responsibility and brand reputation.

Why Tyre Waste Management is Important?

Tyre waste is a growing environmental concern in India. End-of-Life Tyres (ELTs) can persist for decades, causing soil and water pollution. Improper disposal also increases tyre fire risks, releases toxic gases, and creates mosquito breeding grounds, posing public health hazards.

Beyond the hazards, tyre waste presents significant recycling opportunities. ELTs can be transformed into valuable resources, including:

- Crumb rubber: for use in construction, playgrounds, and sports surfaces.

- Retreaded tyres: for reuse, reducing the demand for new tyres.

- Energy recovery: in industrial processes.

Proper tyre waste management not only mitigates these risks but also promotes sustainability and a circular economy.

Who Needs EPR Registration for Tyre Waste?

EPR compliance is mandatory for several stakeholders in the tyre industry. It ensures that End-of-Life Tyres (ELTs) are collected, recycled, and disposed of responsibly, reducing environmental pollution and supporting sustainable practices. Adhering to EPR guidelines also strengthens corporate sustainability and enhances brand reputation.

The businesses required to comply include:

- Tyre producers, importers, and brand owners:

Responsible for placing tyres into the market and managing their lifecycle.

- Automobile manufacturers (OEMs):

Vehicles fitted with tyres fall under their responsibility for EPR compliance.

- Importers of tyres or vehicles with tyres:

Must register under EPR and implement collection and recycling processes.

These stakeholders must register under EPR, maintain accurate records, engage CPCB-registered recyclers, and submit annual reports. Proper compliance ensures legal adherence, environmental responsibility, and contributes to the circular economy by recycling ELTs into products like crumb rubber, retreaded tyres, or energy resources.

Get Service NowRegulations & Legal Framework for EPR Tyre Waste in India

The management of tyre waste in India is governed by a clear regulatory framework to ensure environmental protection and sustainability. The Ministry of Environment, Forest and Climate Change (MoEFCC) issued a notification in 2022 under the Hazardous and Other Wastes (Management & Transboundary Movement) Rules, making it mandatory for tyre producers, importers, and brand owners to implement Extended Producer Responsibility (EPR) programs.

The Central Pollution Control Board (CPCB) provides detailed SOPs and guidelines for EPR Tyre Waste compliance, including proper collection, recycling, and environmentally sound disposal of End-of-Life Tyres (ELTs). CPCB also maintains a registry of authorized recyclers and retreaders to ensure tyre waste is processed responsibly.

By following these regulations, businesses not only stay compliant but also actively contribute to reducing tyre waste, promoting recycling, and supporting a circular economy, while safeguarding their brand reputation and environmental responsibility.

Businesses registered under EPR must adhere to annual compliances and reporting obligations, which include:

- Submitting annual returns on tyre collection, recycling, and disposal activities.

- Maintaining records of tyre volumes managed through authorized recyclers.

- Demonstrating compliance with Tyre Waste Management Rules to CPCB.

Process of EPR Registration for Tyre Waste

Registering for EPR for tyre waste is a structured process designed to ensure that tyre producers, importers, and brand owners manage End-of-Life Tyres (ELTs) responsibly. Following the proper procedure not only ensures compliance with the Tyre Waste Management Rules but also supports sustainable recycling and resource recovery initiatives.

- 1. Application Submission:

Submit the application on the CPCB online portal (eprtyres.cpcb.gov.in), including company details and product information.

- 2. Providing Producer/Importer Details:

Furnish details of tyre brands, volumes sold in the market, and manufacturing/import activities.

- 3. Uploading Required Documents:

Upload mandatory documents such as the certificate of incorporation, GST, PAN, and product specifications.

- 4. Payment of Applicable Fees:

Pay the government-prescribed registration fee through the CPCB portal to proceed with the application.

- 5. Verification by CPCB:

CPCB reviews the application, documents, and payment for accuracy and compliance.

- 6. Grant of EPR Certificate:

Upon approval, CPCB issues the EPR Certificate, authorizing the business to legally manage tyre waste.

Step-by-Step Process:

Note: Following this process ensures that your business is fully compliant with environmental regulations while contributing to the circular economy. It also demonstrates corporate responsibility and strengthens your brand’s reputation for sustainability.

Ongoing Compliance

- Annual Returns:

File annual returns with CPCB detailing the quantity of tyres placed on the market and the amount collected, recycled, or disposed of through authorized recyclers.

- Collection & Recycling Targets:

Meet mandatory recycling or retreading targets as per the Tyre Waste Management Rules, 2022.

- Authorized Recyclers:

Ensure End-of-Life Tyres (ELTs) are handed over only to CPCB-registered recyclers or retreaders.

- Proper Record Keeping:

Maintain transparent records of tyre sales, collection, recycling, and disposal activities.

Renewal of EPR Certification

- Validity of Registration:

EPR Registration for tyre waste is generally valid for 5 years from the date of issue.

- Timely Renewal:

Submit the renewal application on the CPCB EPR portal at least 60 days before the expiry of your current certificate.

- Submission Requirements:

Renewal requires updated compliance reports, annual returns, past performance data, and revised EPR targets.

- Smooth Approval:

Consistent compliance and meeting yearly collection/recycling targets ensure smooth and quick renewal approval.

At SS Global Services, we handle the entire process for you—from preparing documents and filing applications to coordinating with CPCB and securing approvals. Our team ensures timely submissions, smooth EPR renewals, and compliance management, so your EPR Tyre Waste Registration process is fast, hassle-free, and fully compliant with regulations.

Get Service NowDocuments Required for EPR Registration for Tyre Waste

Registering for EPR for tyre waste requires submission of several key documents to ensure compliance with the Tyre Waste Management Rules and facilitate smooth approval by CPCB. Providing complete and accurate documentation helps avoid delays or rejections during the registration process.

The essential documents typically include:

- 1. Company Incorporation Documents :

Certificate of Incorporation, Memorandum & Articles of Association.

- 2. GST, PAN, and CIN Details:

For verification of the company’s legal and tax identity.

- 3. Import/Export License:

If applicable, for imported tyres or vehicles fitted with tyres.

- 4. Product Details:

Information about tyre categories, volume of sales, brand names, and manufacturing/import data.

- 5. Authorized Signatory Documents:

Power of attorney or authorization letter for the person submitting the application.

Note: Keeping these documents ready and well-organized ensures a smooth and fast EPR registration process. Make sure all details are accurate to avoid any delays in approval.

At SS Global Services, we assist our clients in compiling all required documents, verifying them for accuracy, and submitting the application to CPCB, helping you achieve hassle-free compliance with tyre waste regulations.

Get Service NowResponsibilities of Producers under EPR for Tyre Waste

Under the EPR framework for tyre waste, producers, importers, and brand owners are legally responsible for ensuring that End-of-Life Tyres (ELTs) are managed in an environmentally sound manner. This responsibility covers the entire lifecycle of the product, from sale to final disposal or recycling.

Key responsibilities include:

- Collection and Channelization of ELTs:

Ensuring that discarded tyres are collected from the market and directed to authorized recyclers or retreaders.

- Engaging Authorized Recyclers/Retreaders:

Partnering only with CPCB-registered entities to guarantee safe processing and recycling of used tyres.

- Submission of Annual Returns:

Filing accurate reports with CPCB detailing tyre volumes sold, collected, and recycled, as part of compliance requirements.

- Maintaining Records:

Keeping clear and transparent documentation of all recycled or disposed tyre quantities to facilitate audits and regulatory verification.

By fulfilling these responsibilities, businesses not only comply with the Tyre Waste Management Rules but also contribute to a circular economy, reduce environmental impact, and enhance corporate sustainability and brand reputation.

Get Service NowBenefits of EPR Registration for Tyre Waste

Registering for EPR for tyre waste provides significant advantages for businesses, combining regulatory compliance with environmental responsibility. By following EPR guidelines, companies not only stay legally compliant but also enhance sustainability and brand reputation.

Key Benefits of EPR Tyre Waste Certification:

- Legal Compliance:

Fulfil all requirements under CPCB and MoEFCC regulations, avoiding non-compliance issues.

- Avoidance of Penalties:

Reduce the risk of fines or legal actions for improper management of End-of-Life Tyres (ELTs).

- Corporate Sustainability & Brand Reputation:

Demonstrate environmental responsibility and commitment to sustainable practices, enhancing stakeholder trust.

- Contribution to Circular Economy:

Promote recycling, retreading, and energy recovery of tyres, reducing environmental impact and supporting sustainable resource use.

Challenges in Tyre Waste Management

Managing End-of-Life Tyres (ELTs) in India comes with several challenges that can complicate compliance and environmental efforts. One major issue is the lack of an organized collection system, which makes it difficult to gather discarded tyres efficiently from across the market.

Another challenge is the limited number of CPCB-registered recyclers and retreaders. With few authorized facilities available, businesses may face delays or higher costs in processing their tyre waste according to regulatory requirements.

Additionally, high compliance costs for importers and producers can be a concern. Meeting collection, recycling, reporting, and annual return obligations requires careful planning and investment, especially for businesses with large volumes of tyres.

Despite these challenges, proper planning and adherence to the Tyre Waste Management Rules can help mitigate risks, ensure compliance, and contribute to sustainable tyre waste management practices.

How SS Global Services Helps with EPR Compliance

Managing EPR for tyre waste can be complex, involving regulatory compliance, documentation, and coordination with CPCB. At SS Global Services, we simplify this process, providing end-to-end support for tyre producers, importers, and brand owners. Our expertise ensures businesses meet all obligations under the Tyre Waste Management Rules efficiently and without hassle.

We offer comprehensive assistance in every stage of the EPR process, including:

- Expert Guidance:

Advising on regulatory requirements and compliance strategies.

- Application Support:

Preparing and submitting accurate EPR registration applications on the CPCB portal.

- Document Assistance:

Compiling and verifying all required documents for smooth approval.

- Liaison with CPCB:

Coordinating with authorities to expedite approvals and resolve queries.

- Compliance Management:

Guiding on collection, recycling, record-keeping, and annual reporting obligations.

- Ongoing Support:

Ensuring timely renewals, continuous compliance, and adherence to recycling targets.

With our structured approach, businesses can focus on their core operations while confidently managing their EPR responsibilities. Proper implementation not only ensures legal compliance but also contributes to environmental sustainability and supports the circular economy.

Get Service NowFrequently Asked Questions (FAQs)

Managing End-of-Life Tyres (ELTs) can raise several questions for tyre producers, importers, and brand owners. The following frequently asked questions (FAQs) provide clear guidance on EPR Tyre Waste Registration, compliance requirements, responsibilities, and benefits to help businesses understand and implement proper tyre waste management practices.

Our Top Services

At SS Global Services, we offer a complete range of certification and compliance services tailored to meet the needs of manufacturers, importers, and brand owners. From BIS and BEE certifications to EPR, WPC, TEC, and LMPC registrations, our expert-led process ensures fast approvals, minimal delays, and full legal compliance. Our top services are trusted by startups and global enterprises alike for their accuracy, reliability, and support at every step.

BEE registration for electrical appliances ensures energy efficiency compliance in Indian markets.

Mandatory CRS registration for electronics under BIS ensures product safety and performance compliance.

Register under CPCB's EPR policy to manage and dispose of e-waste responsibly and lawfully in India.

Plastic waste certification under EPR ensures legal compliance for producers and brand owners in India.

Battery waste registration ensures safe handling, recycling, and regulatory compliance for all producers.

Tyre producer registration to comply with EPR norms and sustainable waste disposal systems.

Mandatory ETA approval from WPC for importing RF-enabled wireless, Wi-Fi, and IoT devices in India.

Certification under BIS Scheme-X is mandatory for specific products as per Indian regulatory standards.

Telecom and networking devices must be certified under TEC/MTCTE to be legally sold or used in India.

TAC and IMEI registration is required to legally import and sell mobile devices in the Indian market.

Legal Metrology registration for importers ensures proper labelling and packaging of goods in India.

Request Service Today!

Ready to get certified or need expert compliance support? Fill out the form below and our team at SS Global Services will connect with you shortly.

We offer fast, reliable, and hassle-free assistance for all BIS and regulatory certification needs.